The Digital Transformation Opportunity of AI Smart Access Management

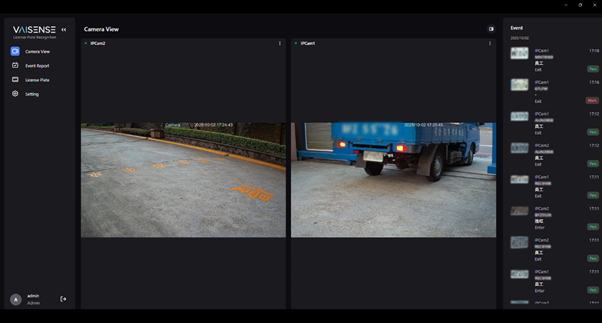

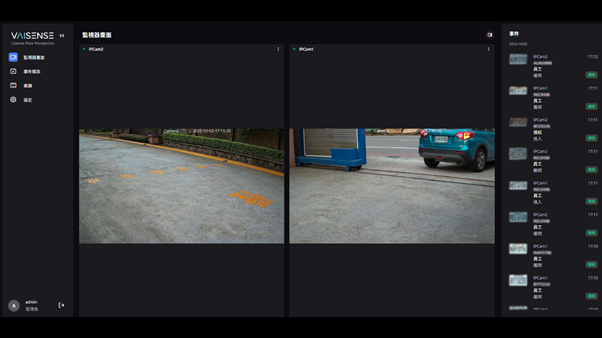

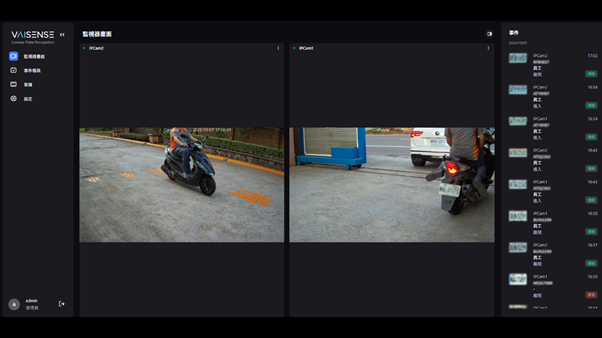

With the rapid advancement of AI technologies, manufacturers are not only embracing automation in production but also driving digital transformation in smart security. Latticework, in collaboration with VQORDER CO., LTD., successfully deployed VAISense Security and VAISense LPR (License Plate Recognition) solutions for Taiwan Cheng Mei Machinery Co., Ltd. By means of AI visual recognition technology, the system provides real-time smart security technology and license plate recognition services for factory entrances and exits, achieving safe, efficient, and intelligent access control.

From Manual to AI Access: Uncovering the Hidden Costs of Traditional Access Control

Before implementing the VAISense Security system, factory access control primarily relied on manual registration and proximity card verification. During peak commuting hours, vehicles frequently formed queues, not only slowing employee movement but also clogging intersections and inconveniencing other road users. When unfamiliar vehicles or suspicious activities appeared on-site, security guards often struggled to identify or track them promptly. Reporting incidents also depended on manual processes, creating security blind spots. In the event of emergencies or property losses, management teams had to spend considerable time reviewing surveillance footage and manual records, leading to difficult tracing and delayed responses.

These challenges, accumulated over time, not only increase labor costs but also become hidden risks to corporate security and operational efficiency. This was precisely the key catalyst for Cheng Mei Machinery's decision to implement the Latticework VAISense intelligent security and license plate recognition system.

The Power of Edge AI: Real-Time Recognition with Zero Delay

Latticework’s VAISense solutions are powered by Edge AI computing, uniquely integrating the high-performance DeGirum AI chip. This allows AI models to run directly on-site via IPC devices with ultra-fast processing.

Within milliseconds, the system can capture and verify license plate data. Compared to traditional RFID cards or manual registration, this approach offers clear advantages:

- No need to stop and wait for recognition

- Real-time access control with reduced human error

- Contactless passage for smoother traffic flow

- Complete data logging and quick search functions

Additionally, the system can detect abnormal vehicle behavior, trigger instant alerts, and seamlessly integrate with existing infrastructure—making it a cost-effective upgrade to traditional access control systems.

Remarkable Results: Efficiency and Security Doubly Enhanced

After implementation, Cheng Mei Machinery experienced significant improvements in access management:

- Higher traffic efficiency: Employees can pass through smoothly during peak hours without waiting.

- Reduced management costs: Less manpower is required for gatekeeping or manual license verification.

- Faster investigation and auditing: Searchable records, event playback, and video matching enable quicker incident response.

- Data ownership: With Edge AI, companies maintain full control over collected data and access rights.

- Enhanced visitor experience: Contactless, automated access reduces friction, providing both employees and guests with convenience and peace of mind.

In addition to making entrance and exit management easier through the fast recording of the VAISense LPR System, the VAISense Security solution not only strengthens safety management, but also indirectly improves the employee experience, enhances the image of the enterprise as a smart factory, and demonstrates the practical value of AI technology in access management in the manufacturing industry.

Driving Industry Upgrades with VAISense AI Security

This successful cooperation demonstrates the outstanding application value of Latticework VAISense security technology in the factory setting, as well as the huge potential of AI in the field of access management. In the future, Latticework will continue to work hand in hand with partners around the world to promote more VAISense AI solution applications, helping industries maintain a competitive edge in the wave of digital transformation. This is not only a successful case of technology introduction, but also a typical example of the integration of traditional manufacturing and smart security, providing the manufacturing industry with a brand-new option for factory safety and access management, and helping enterprises move steadily forward in digital transformation toward the future of smart manufacturing.

- Discover more VAISense features

- Learn more about VAISense Security

- Explore VAISense LPR

Beginnen Sie noch heute mit Edge AI

Unsere Experten sind bereit, Ihnen bei der Einführung einer KI-Lösung zu helfen, die Ihren Anforderungen am besten entspricht und Ihnen hilft, Ihrer Konkurrenz einen Schritt voraus zu sein. Lassen Sie uns reden!

Erhalten Sie die neuesten AI-Insights

Abonnieren Sie den VAISense-Newsletter.